© Uwe Strasser

© Uwe Strasser

Virtual Labs: Getting the Best out of Building Materials

wienerberger optimizes ceramic products and develops innovative solutions in Virtual Labs. Vienna University of Technology is the scientific partner.

© Uwe Strasser

© Uwe Strasser

wienerberger optimizes ceramic products and develops innovative solutions in Virtual Labs. Vienna University of Technology is the scientific partner.

For most people, the word laboratory conjures up images of white coats and microscopes. But what about a virtual laboratory? Well, a collaborative research project between wienerberger and the Vienna University of Technology might have the answer: in the future, product simulations will be carried out and brick products will be optimized in "Virtual Labs".

Bricks are a 100% natural product with many positive characteristics. Their excellent load-bearing strength makes them the material of choice for buildings, they create a consistently pleasant indoor climate all year round and protect building occupants from noise. In the past, developing the best product for specific requirements involved creating prototypes that had to be dried, fired and then tested. Depending on the prototype’s complexity, this process had to be repeated several times - costing time, resources, and energy - to say nothing of the expense involved.

But wienerberger is taking a new route with its Virtual Labs. Trial-and-error is being replaced by computer-based simulations that use mathematical models to calculate and improve the properties of bricks, masonry walls and systems. “This method lets us optimize the physical properties of the products in a targeted manner. For example, we can adjust a brick’s strength, thermal performance, and sound proofing properties to suit specific needs while keeping its weight as low as possible to reduce CO2 emissions” explains Andreas Jäger, Head of International Product Management Wall at wienerberger.

© Kariem et al. (2020)

© Kariem et al. (2020)

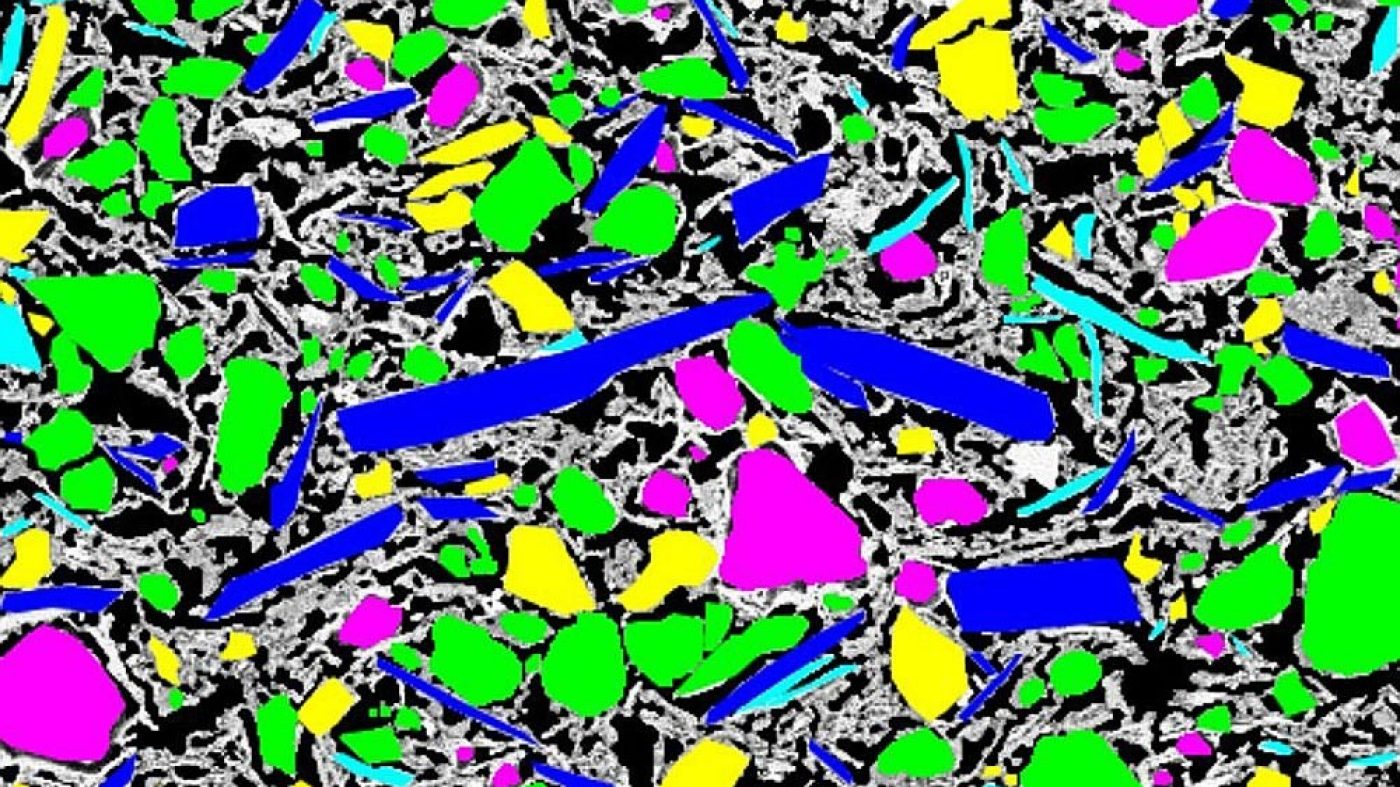

The basis for the micromechanical model: The electron microscope reveals the microstructure of the brick. (Source: Kariem, H., Kiefer, T., Hellmich, C., Gaggl, W., Steiger-Thirsfeld, A., & Füssl, J. (2020). EDX/XRD-based identification of micrometer-sized domains in scanning electron micrographs of fired clay. Materials and Structures, 53(4), 1-20.)

The first step was to analyze the microstructure of the brick and then develop mathematical models to describe its properties. Now that has been completed, three virtual test labs are being set up for different test areas: Ceramics (microstructure optimization), mechanics (design optimization) and production (production process optimization). “With the help of computer simulations, we can quickly determine which change produces the desired effect. We are then in a position to optimize brick products and systems efficiently and in a more targeted manner”, Jäger says.

For example, if the aim is to improve thermal conductivity, first of all a digital diagram of the brick is made and then a formula for the clay is developed. Once the mathematical model is formulated, researchers begin testing various parameters, such as porosity and the hole pattern. This enables them to determine how these parameters influence the thermal conductivity, which in turn helps to optimize the product. Having arrived at the optimum solution, the first prototype is made. The length of this process depends on the complexity and the specific requirements and is complicated by the fact that bricks always have multiple functions to fulfill, including sound insulation, load-bearing capacity, and fire protection.

With the help of computer simulations, we can quickly determine which change produces the desired effect. We are then in a position to optimize brick products and systems efficiently and in a more targeted manner.

The innovative advantage of the Virtual Labs is that they can be used to develop products specifically tailored to customer requirements. “We want to get the very best out of wienerberger’s wide range of specialized products - and the Virtual Labs will vastly improve the efficiency of our product development”, Andreas Jäger says.

The new tools help developers find the optimal clay formula and firing temperatures to achieve the desired properties. Time-to-market can also be reduced by calculating the physical properties in advance. Furthermore, the quality of a brick product depends not only on the composition of the clay but also on how it is processed. “One challenge of brick development is that the physical and chemical properties of clay deposits differ from one country to the next. This makes it hard to find one-size-fits-all solutions” emphasizes Wolfgang Gaggl, Head of Laboratory Hennersdorf at wienerberger.

One challenge of brick development is that the physical and chemical properties of clay deposits differ from one country to the next. This makes it hard to find one-size-fits-all solutions.

The key role sustainability plays at wienerberger is of course reflected in its product optimizations – for example, with reduced product weight, lower firing temperatures and improved thermal insulation. The new methods are intended to reduce energy consumption in production by up to 15 percent and improve thermal insulation properties by almost a third while at the same time permitting thinner wall constructions.

The software for the Virtual Labs is currently being developed at the Vienna University of Technology and in the next step will be implemented at wienerberger. Beyond this project, the company continues to work on product developments and optimization with other partners such as the TU Budapest or the TU Graz. Projects like the Virtual Labs are vital steps towards the future and safeguard innovation leadership.

wienerberger’s Virtual Labs are being developed in collaboration with the Vienna University of Technology as part of the “Innovative Brick 2“ project (2018-2021), a continuation of the “Innovative Brick“ project 2014-2018. The project seeks to optimize brick masonry while taking the production process into account. Both projects are supported by the Austrian Research Promotion Agency (FFG) and the Austrian Climate and Energy Fund.