© Heikki Avent / Wienerberger AS

© Heikki Avent / Wienerberger AS

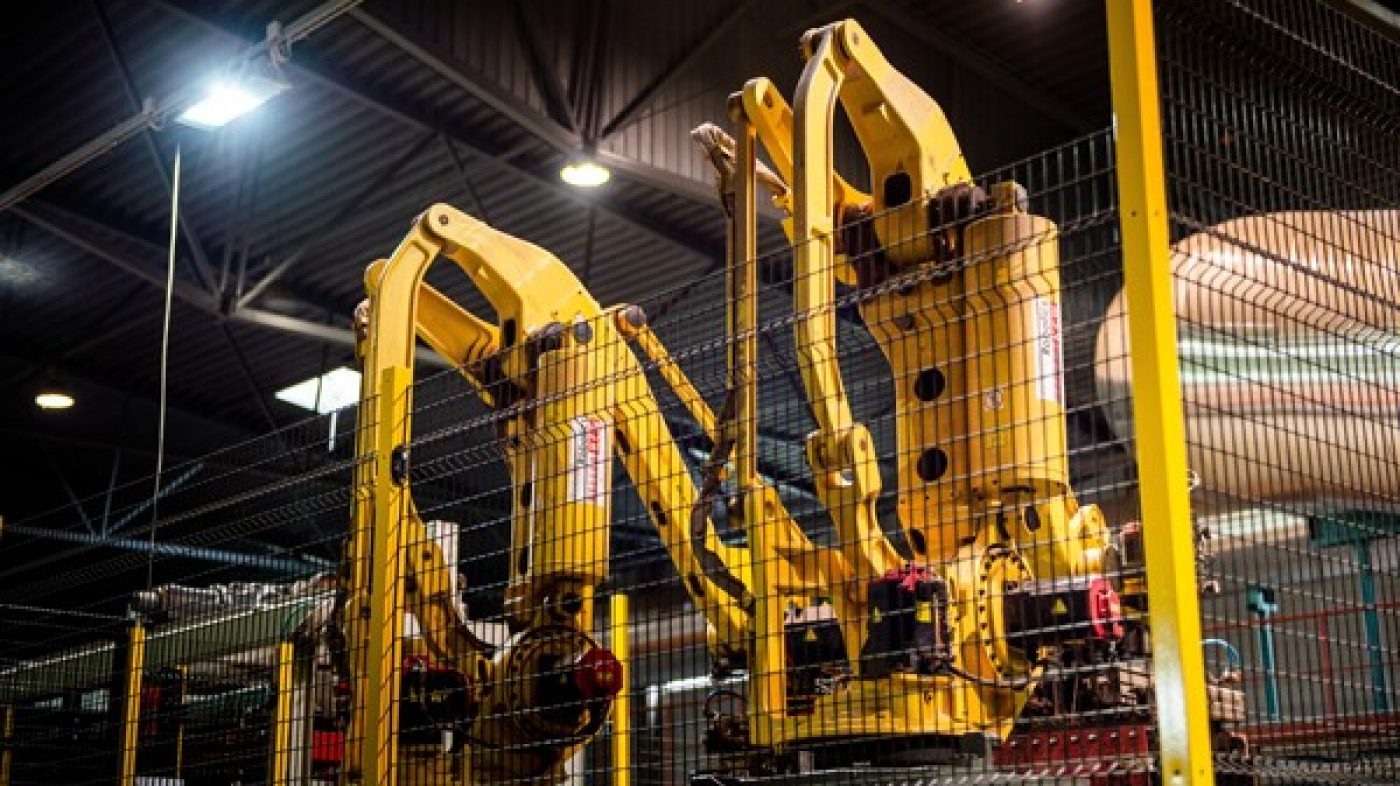

Bricks From an Automated Packaging Line

The products manufactured by wienerberger Estonia at its brick plant in Aseri are sorted and packed automatically – for the environment and more safety.

© Heikki Avent / Wienerberger AS

© Heikki Avent / Wienerberger AS

The products manufactured by wienerberger Estonia at its brick plant in Aseri are sorted and packed automatically – for the environment and more safety.

Greater process efficiency, fewer CO2 emissions, increased safety at work: These are just some of the many advantages digitalization offers for wienerberger’s brick production operations. Impressive proof is provided by the brick plant in Aseri, Estonia, where a new automated sorting and packaging system was taken into service in May 2021.

“Until recently our sorting and packaging system was operated manually; we wanted to change that, says Margus Puusepp, Managing Director at wienerberger Baltics. The company therefore purchased a fully automated packaging line with three industrial robots from Poland. The way it works is simple and effective: Two of the digital helpers lift the bricks and place them on the conveyor for the quality control process during which they are carefully inspected and checked for damage.

The third robot then places the bricks on pallets which are automatically transported to the packaging machine. Approximately two million bricks per month are prepared for shipment this way in Aseri with two to three people working on the line in shifts.

wienerberger invested 450,000 euros in the new sorting and packaging system. This investment also benefits the environment because it cuts the plant’s CO2 emissions. “Thanks to the robots and machines, we can produce more bricks using the same amount of gas. This will help us achieve our goal of reducing our ecological footprint by 10 percent within a year”, says Puusepp. In this way, the Estonian site also supports wienerberger’s ESG (Environmental Social Governance) strategy which, among other things, aims to further reduce the Group’s CO2 emissions by 15 percent compared to 2020.

Thanks to the robots and machines, we can produce more bricks using the same amount of gas. This will help us achieve our goal of reducing our ecological footprint by 10 percent within a year.

The 50 workers at the brick plant also benefit from the new system. After all, handling products that weigh tons every day has an impact on their health. “Easing the physical burden on our colleagues who perform such intensive manual handling operations is extremely important to us. Automated processes can make a decisive contribution to reducing the effects of strenuous manual labor and preventing accidents at work”, says Puusepp.

Our workforce is very interested in the new robots and machines and wants to learn more about how they function. It is an exciting process that improves safety and takes our production to the next level.

The managing director is especially proud of his team’s commitment and willingness to learn. “Our workforce is very interested in the new robots and machines and wants to learn more about how they function. It is an exciting process that increases safety and takes our production to the next level.”

From facing bricks to solid bricks, 21 different types of brick are produced in the Estonian plant. Other products such as brick slips and pavers are also manufactured in Aseri and processed there by the automated sorting and packaging system. “What will the next steps be? Now we have to make the finetuning of the machinery”, says Puusepp. “The machines have to be adjusted to process all the different types of brick as efficiently as possible.”

In the long term, the new system is a key piece of the puzzle when it comes to achieving the factory’s targets. The company’s share of the Estonian market currently stands at around 70 percent, and the aim is to expand this.

Click to learn more

Close