© Steinzeug-Keramo

© Steinzeug-Keramo

Steinzeug-Keramo: Into the Climate-Neutral Future

From the “energy policy agreement“ with Belgium to the SYSTEM.iX pipe system: wienerberger’s Steinzeug-Keramo subsidiary is breaking new ground for decarbonization.

© Steinzeug-Keramo

© Steinzeug-Keramo

From the “energy policy agreement“ with Belgium to the SYSTEM.iX pipe system: wienerberger’s Steinzeug-Keramo subsidiary is breaking new ground for decarbonization.

An increasing worldwide shortage of resources is putting the focus on climate-friendly materials and production methods. As a leading international supplier of building materials and infrastructure solutions, wienerberger has set itself an ambitious target for 2050: a carbon footprint of zero CO2emissions, in line with the European Green Deal. When it comes to decarbonization, the wienerberger subsidiary Steinzeug-Keramo leads by example.

Steinzeug-Keramo is Europe’s biggest manufacturer of vitrified clay pipes and sustainable system solutions for water and wastewater management. As it moves into the future, the company relies on natural resources, energy-efficient production, recycling, re-use and technological innovations. “All our pipes are made wholly of natural raw materials. Each product has between 30 and 50 percent of recycled ceramic material, including scrap from tiles and roof tiles, added to it”, says Yannic Stevens, Operations Director at Steinzeug-Keramo.

“All our pipes are made wholly of natural raw materials. Each product has between 30 and 50 percent of recycled ceramic material, including scrap from tiles and roof tiles, added to it.”

As a natural and completely recyclable material, clay is a virtually unlimited resource. “The biggest advantage of our vitrified clay pipes is their long service life which averages 100 years or more”, says Yannic Stevens. As well as being recyclable, clay products can also be re-used. The continuous Cradle-to-Cradle® recertification process confirms that Steinzeug-Keramo has achieved a closed-loop material cycle. Read more here: Steinzeug-Keramo: Sustainable waste water disposal.

Alongside the circular economy, decarbonization is a key environmental pillar in the wienerberger Sustainability Program 2023: By 2023 CO2 emissions within the wienerberger Group are to be cut by 15 percent compared to 2020. Steinzeug-Keramo is actively contributing to achieving this ambitious target with greater energy efficiency and renewable energies playing a key role. “In production, sustainable value creation and energy-efficient processes are our first priority. The use of 100 percent green electricity help optimize our energy consumption and support decarbonization”, says Yannic Stevens.

“In production, sustainable value creation and energy-efficient processes are our first priority. The use of 100 percent green electricity help optimize our energy consumption and support decarbonization.”

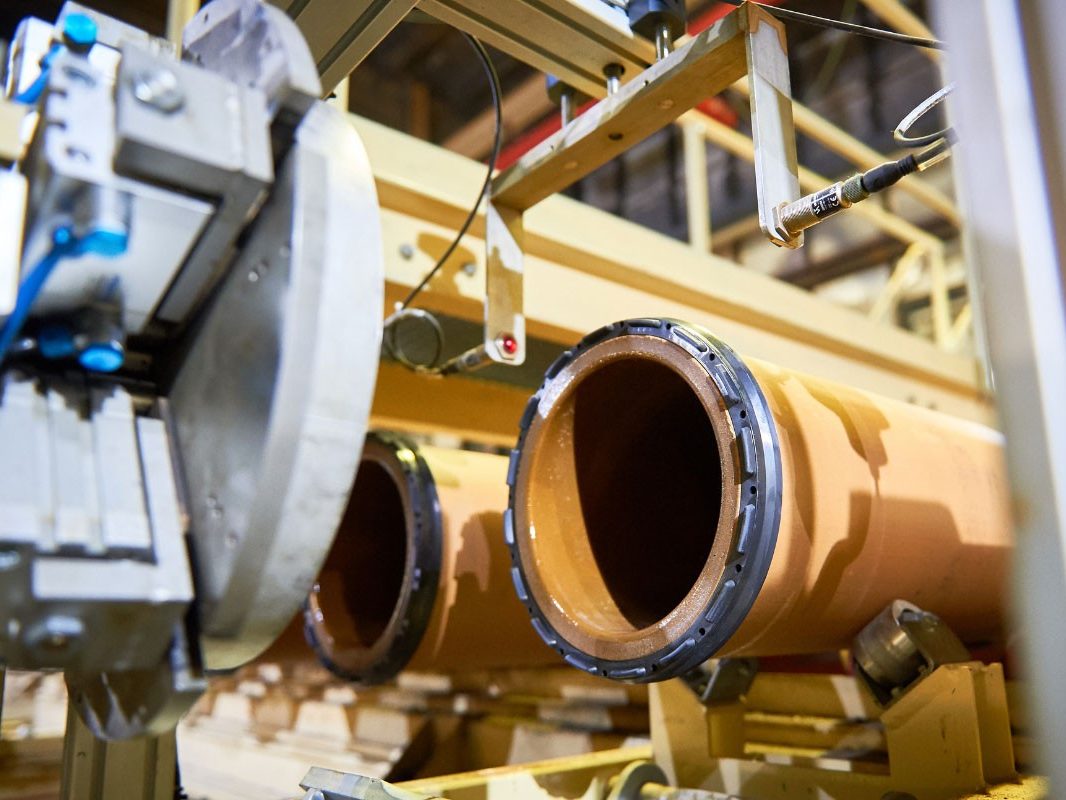

Steinzeug-Keramo produces pipes, manholes, fittings and accessories at two state-of-the-art plants in Germany and Belgium. The CO2 emissions generated at each plant are offset through climate protection projects. In addition, there are further measures for more efficiency such as the optimization of the fast firing kiln with state of the art burner technology in the German production plant. Steinzeug-Keramo also seeks to protect the climate with local partnerships and activities such as the “Energy Policy Agreement” concluded with the Flemish government.

In 2017 Steinzeug-Keramo extended the “Energy Policy Agreement” with the Flemish government in which the company committed to implementing energy-saving measures in the period 2019 to 2022. Several projects are already finalized such as the insulation of the wet buffer, optimization of the drying process, installation of frequency inverters for several ventilators, sealing of kiln cars and so on. With the help of such measures, Steinzeug-Keramo saves around 500 tons of CO2 annually and optimizes its processes.

Steinzeug-Keramo continuously develops new strategies and technologies to support decarbonization. Reducing the weight of products and dematerialization play an important role here – as does the purchase of green electricity. In addition, transport routes from extraction sites to the factory are kept as short as possible and raw materials are transported from Germany to Belgium by ship and in Germany by train from the extraction to the nearest train station thus further cutting CO2 emissions. A monitoring system has been put in place so that activities can be reviewed annually and the action plan adjusted as necessary.

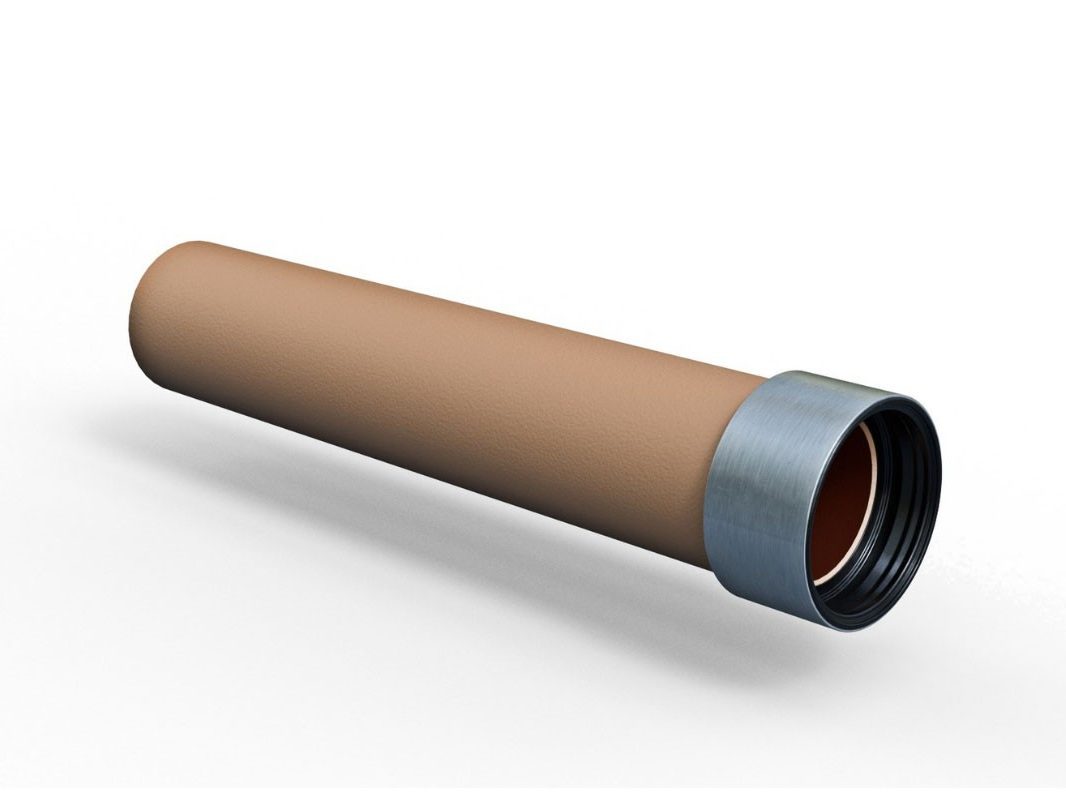

Another example for decarbonization at Steinzeug-Keramo is the innovative SYSTEM.iX: This is a vitrified clay pipe with a smooth end that is flexible, robust and easy to install. During the development of this system solution, material consumption was decreased significantly. This also leads to weightreduction and more pipes fitting on a truck.

Steinzeug-Keramo is working hard to accelerate the pace of decarbonization and improve its performance in further areas of ESG (Environmental Social Governance). Yannic Stevens sees the potential for sustainability in the future in the reuse of wastewater and further reductions in the volume of waste. “Thanks to the natural resources, the closed-loop production cycle and ongoing reduction of CO2-emissions, Steinzeug-Keramo is already at the forefront in sustainability. This should be a reason why customers remain choosing our products and solutions”, Stevens says.

Learn more

Close